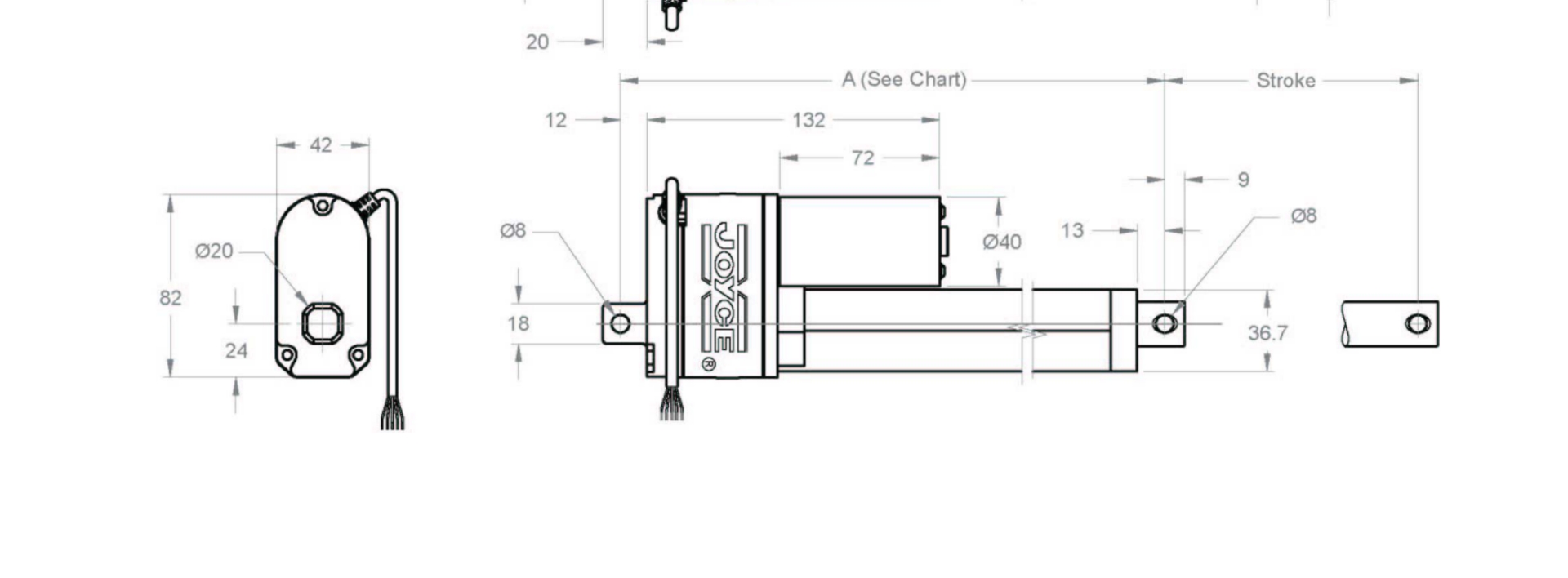

Electric Cylinder actuator models - ComDRIVE, motor mount, standard by Joyce

Standard

The Joyce standard electric cylinder is intended for applications where the customer provides their own drive mechanism. To determine capacity, input torque, and turns-per-inch use the product specification chart. This design can also be used where one or more electric cylinders are being driven by one common drive motor or in combination with the motor mount (direct drive) or ComDRIVE® models listed to the left.

Example part number:

ECAL635C-15.00-STDX-HW08-X

Acme screw (ECA), low lead (L), 6:1 gear ratio (6), 3-ton capacity (3), female clevis (5), clevis base (C), 15 inches rise (15), standard input shaft left hand side of jack (STDX), 8" diameter hand wheel right side of jack (HW08), no additional options (X).

Motor Mount (direct drive)

Joyce motor mount electric cylinders are intended for higher speed applications. Motor mount models can be used in conjunction with one or more of the standard electric cylinders shown above. To determine lifting speed and capacity, view "direct drive" models shown on the quick reference charts for specific sizes of electric cylinders. Standard motors are 3-phase, 230/460 VAC, 60 Hz, and 1750 RPM.

Example part number:

ECAM24104R-9.50-STDX-MMBE-F2

Acme screw (ECA), medium lead (M), 24:1 gear ratio (24), 10-ton capacity (10), male clevis (4), rotated clevis base (R), 9 1/2 inches rise (9.50), standard input shaft left hand side of jack (STDX),145TC motor mount (MMB) with 1 1/2 HP motor (E) on right hand side, epoxy paint (F2).

ComDRIVE®

Joyce ComDRIVE® models include a right angle gear motor mounted to the right or left side of the standard model. ComDRIVEs are intended for applications requiring heavy lifting capacities at speeds up to 34 inches per minute (acme screw) and 104 inches per minute (ball screw). ComDRIVE models can be used in conjunction with one or more of the standard electric cylinders shown above. To determine lifting speeds and capacity, refer to the quick reference charts for specific sizes of electric cylinders.

Example part number:

ECAH8206F-52.25-P1CL-ENCX-M3

Acme screw (ECA), high lead (H), 8:1 gear ratio (8), 20-ton capacity (20), female clevis with pin (6), flange base (F), 52 1/4 inches rise (52.25), 10:1 reducer with a 3 horsepower motor mounted to left hand side of jack (P1CL), encoder on right side of jack (ENCX), single phase motor (M3).

Motor Controls:

Joyce/Dayton offers motor controls ranging from simpleMotor Starters to complex positioning systems and Custom controls. Every system that is powered by an electric motor requires a control system. At Joyce, we know that choosing the best option can sometimes be a challenge. That’s why our Engineers are available to help you through the process.