Choosing Linear Motion Technology for High-Precision Applications

Linear motion technology is critical for aerospace, robotics, manufacturing, and other applications requiring high precision. A well-designed system enables accurate, controlled movements and improves the overall functionality of various types of equipment and machinery.

Comparing Machine Screw Jacks and Ball Screw Jacks for Heavy Lifting

Screw jacks or “jack screws” are machines that can lift moderate and heavy loads. They're commonly used in industrial equipment and complex machinery and come in many sizes, styles, and forms.

Take a closer look at the differences between machine screw jacks and ball screw jacks to decide which one performs best for your heavy lifting applications.

Ball Screws vs. Lead Screws: Which is Right For Your Screw Jack Application?

Screw-driven jacks are the most popular devices used to convert the rotary motion of a motor into linear movement. However, there are two common types of screw-driven systems to choose from: ball screws and lead screws. In this blog, we’ll cover the benefits, drawbacks, and applications of both ball and lead screws to help you determine which option is best for your needs.

Machine Screw Jacks vs. Ball Screw Jacks

Engineers and designers frequently use screw jacks in the design of lifting and positioning equipment. They know that mechanical jacks offer reliable lifting and holding options that can be easily incorporated into their systems.

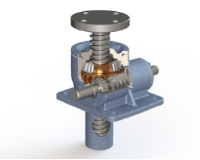

Understanding the 3 Types of Machine Screw Jack Designs

Screw jacks that are properly selected and maintained will reliably lift, position, support or hold industrial loads for years. Incorporating them into mechanized applications is a fairly simple matter once jack designs are understood.

Screw jacks that are properly selected and maintained will reliably lift, position, support or hold industrial loads for years. Incorporating them into mechanized applications is a fairly simple matter once jack designs are understood.

The basic components of machine screw jacks are lifting screw, gear set, and thrust bearing.

Multi-jack Systems

Joyce Lifting & Linear Motion Systems

Joyce/Dayton screw jacks and lifting systems offer wide-ranging lifting and positioning solutions for diverse industries. Our robust jacks reliably move and accurately position loads up to 250-tons. Joyce configures jacks with components such as motors, gear reducers, shafting, coupling, and motion control devices to create complete multi-jack systems.

What Are the Benefits of IP69K Equipment?

An IP rating denotes a product's ability to prevent the ingress of certain fluids or particles that would negatively impact the functionality of its components. When a piece of equipment is likely to encounter high temperature, high pressure wash down situations and needs to be frequently cleaned without incurring damage, using IP69K-rated equipment is an advantageous solution.

Product Integration and Speedy Delivery with EDrive Actuators

The first step to accelerating product delivery is to align your team, customers, and stakeholders on the goals and vision of your product. Doing this will help define the scope of the project, prioritize the right features, and clarify the product's value proposition.

Volumetric Filling Equipment Actuators

Volumetric filling equipment is utilized in numerous industries that require precise filling of containers with pastes, liquids, and other viscous products. Actuators are essential in these systems, as they help drive the filling mechanism with optimal accuracy and reliability.