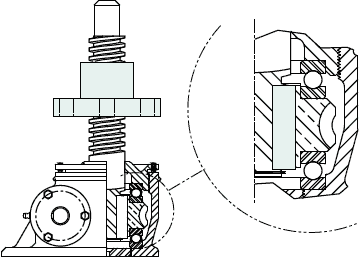

Translating Design

A driven worm acts on an internal wormgear, which in turn drives a lifting screw to extend or retract. As the lifting screw translates through the body of the jack, inherent screw rotation is prevented by an attached load or mounting structure that is anchored to resist rotation.

This design is available for:

- Machine Screw Jacks

- Machine Screw ComDRIVEs®

- Stainless Steel Jacks

- Metric Screw Jacks

- Ball Screw Jacks

- Ball Screw ComDRIVEs®

- Bevel Gear Jacks

- Bevel Ball Actuators

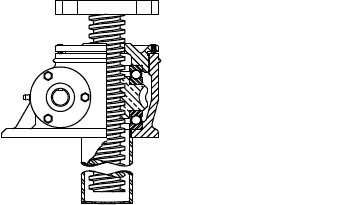

Keyed Design

Some loads do not prevent lifting screw rotation. These applications require a keyed jack. A key, fixed to the jack housing and inserted into a keyway milled into the lifting screw, forces the lifting screw to translate without rotating. Several dimensions of the keyed jack differ from the translating jack – check the keyed jack drawings for each jack model.

This design is available for:

- Machine Screw Jacks (except WJ250)

- Machine Screw ComDRIVEs®

- Stainless Steel Jacks

- Metric Screw Jacks

- Bevel Gear Jacks

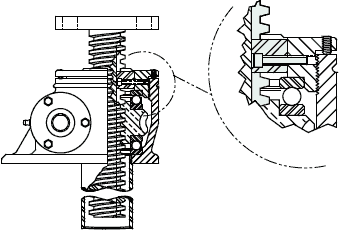

Keyed for Traveling Nut (KFTN) Design

A keyed for traveling nut jack (sometimes referred to as a rotating screw jack) features a lifting screw keyed to the wormgear as a single unit, forcing the lifting screw to rotate, but not translate. A flanged traveling nut, attached to the load, is driven by the rotation of the lifting screw. This type of jack is ideal for applications that cannot accommodate a screw protection tube or that require a flush mount. Refer to the keyed for traveling nut (KFTN) dimensional drawings for each jack model.

This design is available for:

- Machine Screw Jacks

- Machine Screw ComDRIVEs®

- Stainless Steel Jacks

- Metric Screw Jacks

- Ball Screw Jacks

- Ball Screw ComDRIVEs®

- Integrated Actuators

- Bevel Gear Jacks

- Bevel Ball Actuators