"The inherent design of the 50-ton machine screw jack from Joyce/Dayton doesn't let it backdrive under the weight of the roof panels … a critical factor in controlling the roof safely."

Uni-Systems LLC

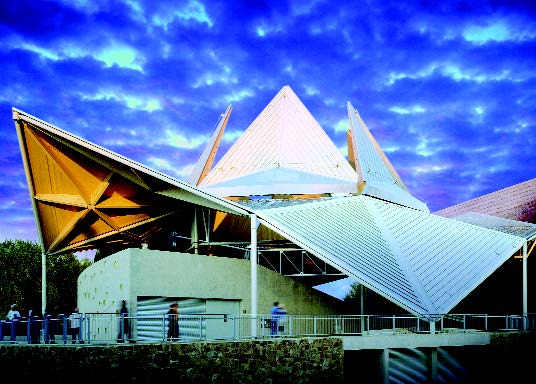

Patrons of Rock Valley College's Starlight Theater love to enjoy performances under the stars … except when it's raining. The theater's director wanted to keep the under-the-stars experience, minus the rainouts, so architects designed a unique opening roof that uses the theater's name for inspiration. At the click of a mouse, six triangular panels open in harmony to form a perfect star shape… under the stars.

Almost a performance by itself, this 90-ton marvel seems to float above the crowd, with all moving mechanisms hidden from view. Minneapolis-based Uni-Systems LLC was responsible for the design and installation. Even though the company's retractable roof resumé includes Houston's Minute Maid Park and Reliant Stadium, this project required a solution unlike any in their experience.

One of the critical components to the solution's success was a 50-ton machine screw jack from Joyce/Dayton.

WHY JOYCE JACKSCREWS?

Starting with a standard “off the shelf” product and adapting it to meet the customer's needs is one of Joyce/Dayton's strengths. The Joyce/Dayton engineering team is ready, willing and uniquely able to help you design and install a solution to virtually any lifting or positioning application. Joyce® can do this with quicker delivery and better pricing than the competition.

Since 1873, the Joyce/Dayton Corp., with headquarters based in Dayton, Ohio, has been one of the premier manufacturers of rugged, heavy-duty mechanical and hydraulic lifting and positioning equipment. From leveling log homes and ship dry-dock transfers to stage and ergonomic lifts, Joyce/Dayton has handled the toughest applications imaginable. With unmatched engineering and technical expertise, Joyce® can provide custom solutions in a time-and price-sensitive manner, turning ideas into working solutions. For more information about the Joyce/Dayton Corp., contact Joyce/Dayton.

Unique Features

- Versatile Joyce® Machine Screw Jacks lift and precisely position loads from 250 lbs. to 250 tons

- Upright or inverted, these precision jacks operate at full capacity whether the load is in tension or compression, and are self locking under full lifting capacity

- Heat treated alloy steel worm shafts, aluminum/bronze worm gears and tapered roller or ball bearings provide rugged reliability

- Spherical bearings at each end of the jack allow for any misalignment between roof components

How the system works

The 50-ton Joyce® jack sits between the roof panel frame and torque tube in a double-clevis arrangement to power each panel. As the machine screw jack extends out, the panel slowly rises to its fully open position. The inherent design of the Joyce® machine screw jack doesn't let it backdrive under the weight of the panel alone, as opposed to a ballscrew jack. Spherical bearings on the jack ends allow the jack to “float”, helping all components stay level throughout the entire motion.