Worm Gear Screw Jacks:

Types, Benefits & Selection Guide

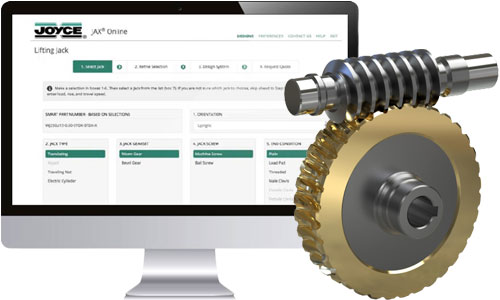

Worm gear screw jacks are a popular option for many applications and industries. At Joyce/Dayton we offer a variety of worm gear screw jack models as well as more advanced options. Many experienced operators prefer using worm gears over conventional gear sets due to their unique capabilities to reduce speed, improve torsion, and provide superior shock absorption. As an industry-leading manufacturer of worm gear screw jacks, Joyce/Dalton Corp. offers a wide selection of high-quality products.

What is a Worm Gear?

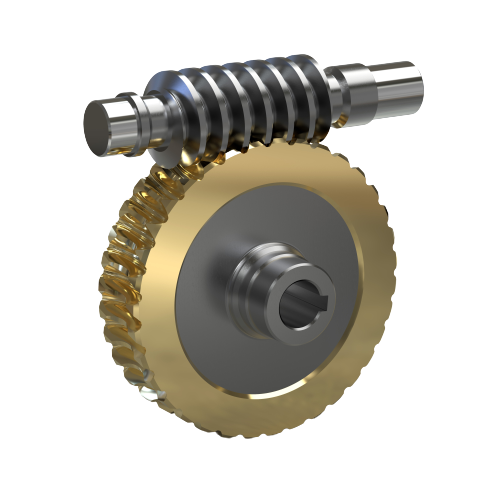

Worm gears can change the direction of shaft rotation, increase the torque of non-parallel rotating shifts, and efficiently decrease speed. The staggered shaft gear utilizes the threads cut into a cylindrical bar to create motion between the shafts.

While worm gears are somewhat inefficient compared to other gear types, they can produce speed reduction in tight, compact spaces, making them beneficial in many various industrial applications.

A worm gear consists of a worm and worm wheel. The ability to reduce speed varies based on the number of worm threads and the number of teeth on the worm wheel.

Advantages of Worm Gear Screw Jacks

Worm gears must be manufactured with high-quality standards to ensure all screw jack requirements are met for proper operation and effectiveness. Worm gears provide the following advantages for a range of applications. Advantages include the following:

Increased Torque

Increased Torque Reduced Speed

Reduced Speed Smooth, Quiet Operation with Proper Lubrication and Mounting

Smooth, Quiet Operation with Proper Lubrication and Mounting Good Meshing Effectiveness

Good Meshing Effectiveness Energy Savings

Energy Savings Low Maintenance Commitments and Costs

Low Maintenance Commitments and Costs

Performance Advantages for Worm Gear Applications

Using worm gears in our screw jacks offers numerous advantages. These high-performance gears exhibit a smooth, simple design and are typically light in weight, equivalent to less than one-third the weight of a similarly-sized spool. Not only are worm gears durable and reliable, but they also offer the following performance advantages for screw jacks:

- Worm gears can provide significantly higher torque when compared to other gear types.

- A single worm gear can provide the necessary speed and power for rotating the shaft of the screw jack.

- The material used for creating the worm gear in the gear train provides an affordable option for manufacturing.

- Compared to a conventional worm, worm gears deliver superior durability.

- A worm gear has one of the most reliable transmissions.

- Offers a longer transmission life span for your screw jacks

- In comparison to other mechanical transmissions, a worm gear proves highly durable and efficient.

Types of Worm Gear Screw Jacks From Joyce/Dayton

A primary benefit of worm gears is the ability to offer torque multiplication and gear reduction in a compact footprint. The assembly and positioning of the teeth are crucial in worm gear screw jack design as it determines how the gears connect, with variations depending on how they touch. Most industrial applications rely on cylindrical worm gears but can also be enveloping or straight and cone. Worm gear faces can be either hobbed, concave, or straight.

Joyce/Dayton offers many different types of worm gear screw jacks, which are highly efficient and can precisely lift and position loads. The ball screw worm gear jacks can operate inverted or upright and in compression or tension at full capacity. They are available in KFTN and Translating designs and require an external locking device or brake to hold the position. The following worm gear screw jack models are available in a variety of gear set ratios:

Selecting a Worm Gear Screw Jack

The wide assortment of shapes, designs, and dimensions make worm gears adaptable for numerous machines and devices. When selecting a worm gear screw jack, considering the following factors will ensure proper functioning:

- The Type Of Worm Gearbox

Understand the differences between single envelope, double envelope, and non-enveloping gearboxes to determine which type is best suited for your application.

- Desired Applications

Understand the torque, velocity, and power requirements of your application to ensure you choose a gearbox that fulfills the mechanical requirements.

- Material Preferences

The materials used to construct gearboxes must be durable to withstand the consistent wear and tear the assembly will be exposed to. Our standard worm gear material is aluminum bronze.

Features of Worm Gear Screw Jacks

Worm gears prove beneficial for screw jacks in various applications. Worm gears are often preferred for screw jacks in applications that require a massive reduction ratio, increased torque, or a high reduction in speed. A conventional gear would have to make several reductions before achieving the same reduction level capabilities of a single worm gear, which has fewer moving parts, reducing the risk of failure. Worm gear screw jacks are commonly used in these applications:

Noise Reduction

Noise Reduction

Worm gears operate quietly, making them suitable for noise-sensitive applications like medical devices and precision machinery.

Fast Stopping

Fast Stopping

The self-locking property of worm gears ensures quick stopping, useful in elevators and lifting systems.

Space Efficiency

Space Efficiency

Compact worm gears transmit high torque in limited space, beneficial for compact machinery and equipment.

Shock Absorption

Shock Absorption

Worm gears absorb shocks due to their sliding contact design, ideal for construction and material handling.

Torsional Stability

Torsional Stability

High torsional stability prevents back driving, crucial in robotics and CNC machinery.

Tuning and Adjustment

Tuning and Adjustment

Worm gears allow precise adjustments, valuable for applications like valve control.

Non-Reversible Applications

Non-Reversible Applications

The self-locking feature makes worm gears perfect for winches, hoists, and conveyor systems.

Conveyor Belts

Conveyor Belts

Worm gears prevent belt reversal, ensuring material stays in place during material handling.

Automatic Door Systems

Automatic Door Systems

Worm gears are used in automatic doors for controlled motion and secure closing without continuous power.

Automotive Steering Systems

Automotive Steering Systems

Worm gears provide torque conversion and reduction for smooth vehicle steering.

Contact Joyce/Dayton to Learn More About the Benefits of Worm Gear Screw Jacks

Since 1873, Joyce/Dayton Corp. has been the premier manufacturer of lifting equipment, actuators, and screw jacks equipment in North America. We have a long history of continuous operation, designing, and manufacturing high-quality products unparalleled in the industry, providing our customers with innovative solutions to meet their specific needs.

Contact Joyce/Dayton or request a quote to learn more about our products and see how our industry knowledge and expertise can provide you with the best choice of worm gears for your next application.