2.500 In. Diameter - 0.500 In. Lead

2.500 In. Diameter - 0.500 In. Lead

This 2.500 inch diameter ball screw has a 0.500 inch lead. Corresponding standard capacity ball nuts with right-hand threads are available.

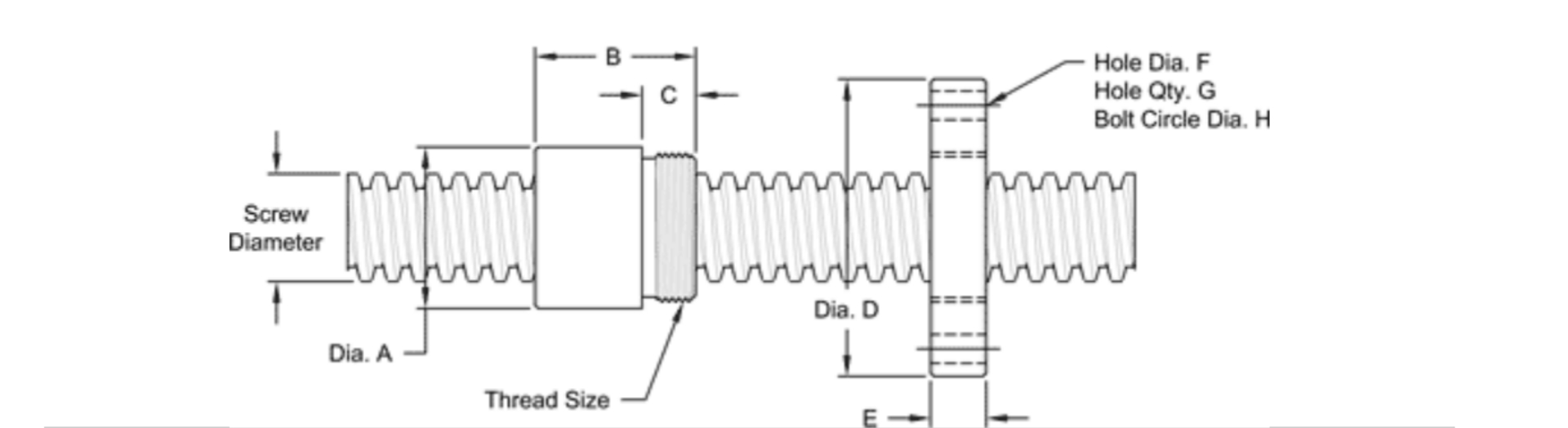

| Ball screw specifications | RH |

|---|---|

| Ball screw part no. | BS 250 R 050 A |

| Nominal ball circle diameter | 2.500 in. |

| Lead | 0.500 in. |

| Screw diameter | 2.540 in. |

| Root diameter | 2.220 in. |

| Screw weight | 14.98 lb./ft. |

| Torque to raise 1 pound* | 0.089in.-lb. |

| Maximum screw length | 24 ft. |

* Torque to raise 1 pound = 0.177 x inches lead x pounds load

Standard Capacity Ball Nut Specifications (S)

| Ball nut specifications | RH |

|---|---|

| Ball nut part no. (standard capacity) | BN 250 R 050 S |

| Ball nut with flange part no. | BF 250 R 050 S |

| Dynamic load capacity** | 22,000 lb. |

| Static load capacity | 155,500 lb. |

| Ball nut weight | 12.09 lb. |

| Nominal ball dia. (avg. ball qty.) | 3/8 in. (186) |

| Flange part no. | FL-3625 |

| Wiper kit part no. | WK-70 |

** for 1,000,000 inches

High Capacity Ball Nut Specifications (H)

| Ball nut specifications | RH |

|---|---|

| Ball nut part no. (standard capacity) | BN 225 R 050 H |

| Ball nut with flange part no. | BF 225 R 050 H |

| Dynamic load capacity** | 29,700 lb. |

| Static load capacity | 213,000 lb. |

| Ball nut weight | 11.22 lb. |

| Nominal ball dia. (avg. ball qty.) | 3/8 in. (237) |

| Flange part no. | FL-3137 |

| Wiper kit part no. | WK-60 |

** for 1,000,000 inches

2D/3D Drawings

Login to access 2D/3D Drawings

Product Media

- Ball screws are made from alloy steel and case hardened to Rc56 (minimum).

- A black oxide finish is applied to prevent corrosion during shipping and for a brief storage period.

- The rust inhibiting properties of the screw lubricant offers additional corrosion resistance.

- Ball nut housings are steel with case hardened threads. A black oxide coating provides additional protection.

- Flanges are constructed of steel with a black oxide coating.

Sample Part Number:

Click on the part number to reveal additional information about the screw design and shaft codes.

Thread Form

B: Ball Screw

Component

A: Assembly

S: Screw - without ball nut or bearing mounts

Screw Diameter - Thread direction - TPI (English)

| Dia/TPI | Code |

|---|---|

| 5/8 - .200* | 063 R 020 |

| 3/4 - .200 | 075 R 020 |

| 3/4 - .500 | 075 R 050 |

| 1 - .250* | 100 R 025 |

| 1 - .500 | 100 R 050 |

| 1 - 1.000 | 100 R 100 |

| 1 1/2 - .500 | 150 R 050 |

| 1 1/2 - 1.00 | 150 R 100 |

| 1 1/2 - 1.875 | 150 R 188 |

| 2 1/4 - .500 | 225 R 050 |

| 2 1/2 - .500 | 250 R 050 |

| 3 - .660 | 300 R 066 |

| 4 - 1.000 | 400 R 100 |

R – Right-hand – all thread diameters/leads are available with right hand threads

L – Left-hand *- Substitute an ”L” in the part number for left hand leads

Screw Material

A: Alloy Steel

First End of Screw

(Flange or threaded end of nut always faces second end)

| Bearing Mount Options | Machining Options (choose one that corresponds to the bearing block) |

|---|---|

| SB - Simple Single* | 1N – Threaded shaft only |

| DB - Simple Double | 2K – Thd Shaft w Kwy, 2L – Thd Shaft no Kwy, 2N – Threaded shaft only |

| FB - Fixed Double | 3K – Thd Shaft w Kwy, 3L – Thd Shaft no Kwy, 3N – Threaded shaft only |

| XX - No Bearing | 4K – Shaft w Keyway, 4L – Shaft no Keyway, 4N – Support only, XX – No Machining |

(When selecting ”XX – No Bearing”, choose from mounting options 1K through 4N or XX, above)

* All Simple Single bearing mounts are designed for radial loads only

Second End of Screw

(Flange or threaded end of nut always faces away from second end)

| Bearing Mount Options | Machining Options (choose one that corresponds to the bearing block) |

|---|---|

| SB - Simple Single* | 1N – Threaded shaft only |

| DB - Simple Double | 2K – Thd Shaft w Kwy, 2L – Thd Shaft no Kwy, 2N – Threaded shaft only |

| FB - Fixed Double | 3K – Thd Shaft w Kwy, 3L – Thd Shaft no Kwy, 3N – Threaded shaft only |

| XX - No Bearing | 4K – Shaft w Keyway, 4L – Shaft no Keyway, 4N – Support only, XX – No Machining |

(When selecting ”XX – No Bearing”, choose from mounting options 1K through 4N or XX, above)

* All Simple Single bearing mounts are designed for radial loads only

Ball Nut Properties

S - Standard Capacity

H - High Capacity

U - Ultra Capacity

X - No ball nut

Other Options

F - With Flange

B - With Flange and Wipers

W - Wipers

X - No Options

Screw Length 000.00"

Enter value in inches with decimal if needed

Note that available screw length varies among screw sizes.

SB Screw End Conditions

| Screw Number | Bearing Mount No. | oS1 | A1 | A2 | A3 | A4 | A5 | A6 | o A7 | A8 | A9 | A10 | A11 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| BS250R050A | 2.1659 | 1.770 | 1.120 | 0.86 | 0.315 | 1.142 | 2.225 | 4.13 | 2.157-18 UNS | W-11 | N-11 | 6311 | |

| 2.1653 | 0.313 |

DB Screw End Conditions

| Screw Number | Bearing Mount No. | oS1 | oS2 | A1 | A2 | A3 | A4 | A5 | A6 | A7 | A8 | A9 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| BS250R050A | 2.1659 | 1.875 | 8.40 | 5.40 | 4.700 | 1.142 | 0.063 | 2.157-18 UNS | W-11 | N-11 | 1/2 x 1 1/2 | |

| 2.1653 | 1.874 |

FB Screw End Conditions

| Screw Number | Bearing Mount No. | oS1 | oS2 | A1 | A2 | A3 | A4 | A5 | A6 | A7 | A8 | A9 | A10 | A11 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| BS250R050A | 2.1659 | 1.875 | 10.10 | 7.35 | 6.50 | 5.608 | 1.142 | 3.350 | 0.035 | 2.157-18 UNS | W-11 | N-11 | 1/2 x 1 1/2 | |

| 2.1653 | 1.874 |